Electronics Industry Thermoforming Solutions

Introduce your next-generation electronic product with confidence by partnering with CW Thomas for thermoformed anti-static trays, enclosures, and protective covers. Whether you’re an emerging tech company or a global leader in electronics, we are committed to helping you bring your innovative designs to life with precision and efficiency, ensuring a smooth transition from concept to production.

TRUSTED BY LARGE AND SMALL ORGANIZATIONS WORLDWIDE

As the demand for electronics continues to expand, CW Thomas remains at the forefront, offering custom thermoforming solutions to meet the unique needs of this rapidly evolving industry. From precision components to high-quality protective enclosures, our thermoformed products provide the necessary durability, protection, and precision for today’s cutting-edge electronics. With decades of experience and a commitment to innovation, CW Thomas helps electronics manufacturers streamline their processes and ensure the highest quality standards.

At CW Thomas, we understand the critical role thermoforming plays in producing reliable, functional components for the electronics industry. Our solutions are designed to meet the exacting demands of electronic manufacturing environments, ensuring that our customers receive products that enhance both performance and protection. Key applications include:

- Anti-Static Component Trays:

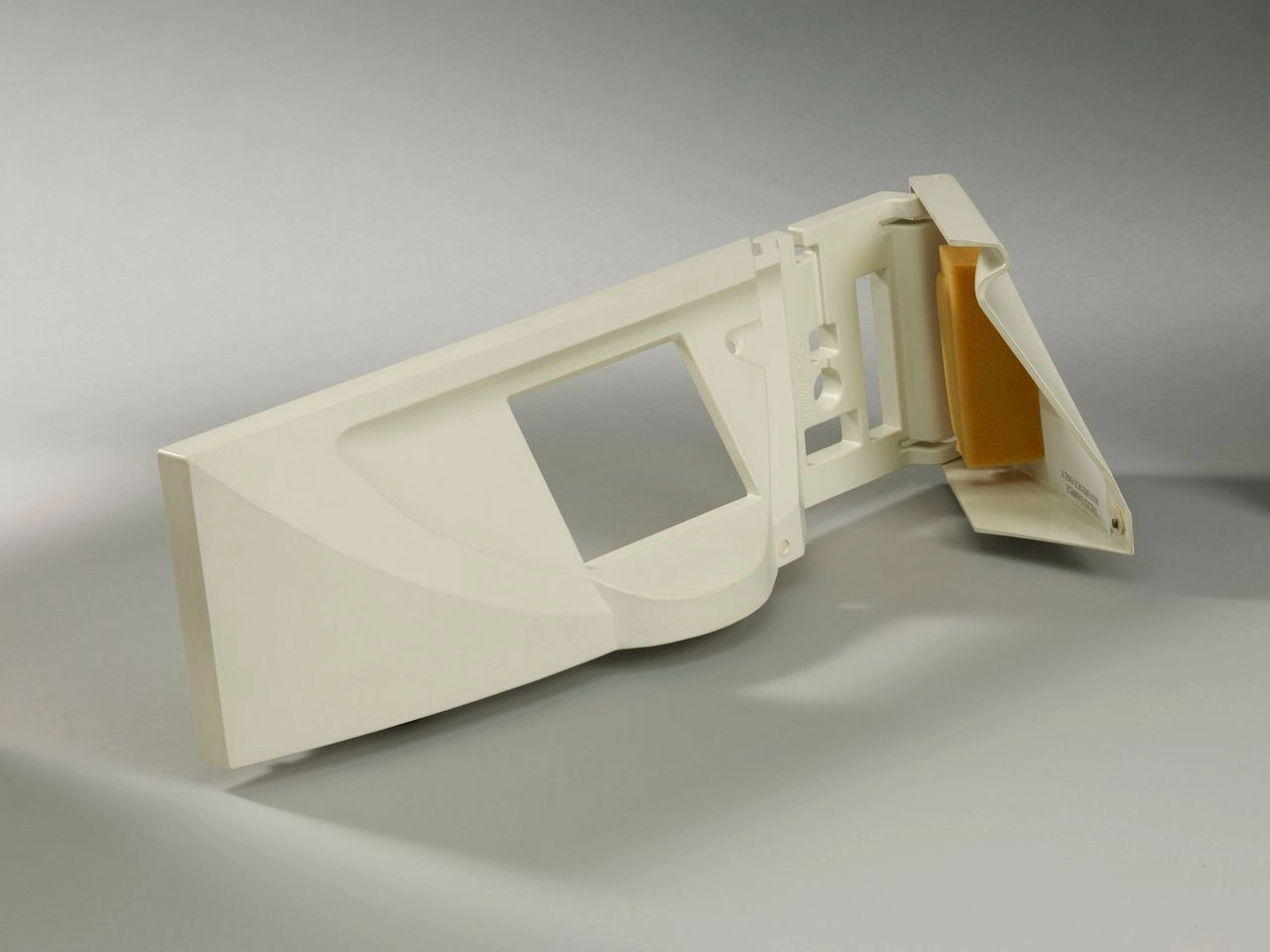

Utilizing materials such as PETG Anti-Static, CW Thomas produces trays that reduce static buildup, ensuring the safe transport and handling of sensitive electronic devices. - Enclosures for Electronic Equipment:

They manufacture durable and lightweight enclosures for various electronic devices, providing protection and contributing to a sleek, modern design. These enclosures can be customized with specific colors, surface textures, and branding elements. - Video Bezels:

CW Thomas produces precision-formed video bezels that enhance the aesthetic appeal and functionality of electronic displays, ensuring a seamless fit and finish. - Theft-Protection Packaging:

To help deter theft, they offer thermoformed packaging solutions that securely encase electronic products, providing both protection and visual appeal.

From Concept to Reality:

Transform your initial design, whether it’s a simple sketch or detailed CAD drawings, into a fully realized product with our streamlined process:

- Collaborative Design Review:

We partner with you to explore design enhancements, improve manufacturability, and accelerate time to market. - In-House Tooling Expertise:

Our skilled team designs and builds precise tooling, ensuring accurate and efficient production. - Rapid Prototyping:

Swiftly validate your design through rapid prototyping, allowing for efficient iterations and adjustments. - Seamless Manufacturing and Assembly:

Once your final design is approved, we seamlessly move into production and assembly, providing a turnkey solution tailored to your needs.

Uncompromising Quality for Peace of Mind:

Rest assured that your project is in capable hands, backed by our commitment to delivering impeccable quality:

- Certified Quality Management: Our ISO 9001:2015 and AS:9100 certifications validate our dedication to upholding stringent standards throughout the manufacturing process.

- Robust Quality Control: From design to final packaging, our comprehensive quality control procedures ensure your product meets or exceeds engineering and technical specifications.

Partner With CW Thomas for Your Electronics Thermoforming Needs

At CW Thomas, we are dedicated to providing electronics manufacturers with high-quality, cost-effective thermoforming solutions that meet the unique challenges of the industry. Whether you need anti-static trays, protective enclosures, video bezels, or theft-prevention solutions, our team has the experience and technology to bring your ideas to life.