Pressure Forming Solutions for the Aerospace Industry

Specializing in Aerospace Applications

At CW Thomas, we specialize in providing exceptional thermoforming solutions for the aerospace industry. Our pressure forming techniques are particularly well-suited for creating comfort-enhancing, aesthetically pleasing, and durable products such as aircraft seating components. With a focus on delivering enduring beauty, maximum value at minimum cost, and ensuring quality and safety, we are committed to meeting the unique challenges faced by the aerospace industry.

TRUSTED BY LARGE AND SMALL ORGANIZATIONS WORLDWIDE

Why Choose Pressure Forming?

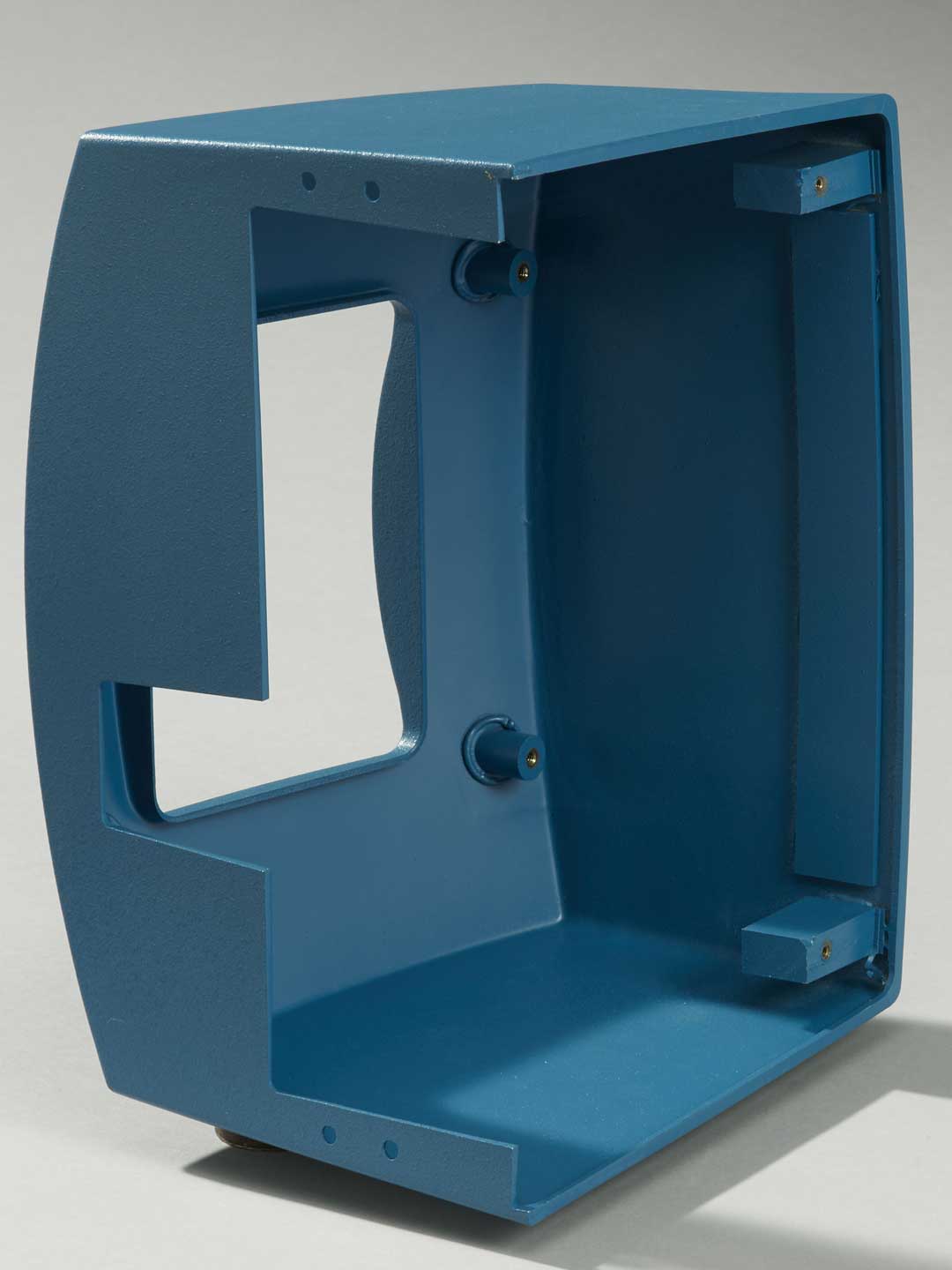

Enduring Beauty:

- Consistent parts with precise detail and intricate undercuts.

- Great depth and functionality, including embedded logos and reverse angles.

- Fewer seams and superior aesthetics.

- Small tight corners, selective texturization, ribs, and molded-in vents can be accurately formed.

Maximum Value at Minimum Cost:

- Economical for prototypes or low-volume production (less than 5,000 pieces per year).

- Lower up-front tooling costs compared to injection or structural-foam molding.

- Multi-part assembly from a single tool saves on overall production costs.

Shrink Your Time to Market:

- Faster tooling manufacture time compared to injection molding.

- Expedited design process and time to market.

Quality and Safety You Can Count On:

- ISO 9001:2008 and AS:9100 certified for exceptional quality control.

- Compliant materials meeting FAR 25.853(a) and FAR 25.853(d), ABD0031, and D6-51377 standards.

- Boeing and Airbus flame, smoke, and toxicity requirements for aircraft interiors.

Have a technical Question? Ask Us

Aerospace Thermoforming Applications and Products:

Our pressure forming capabilities cater to a range of applications and products in the aerospace industry, including:

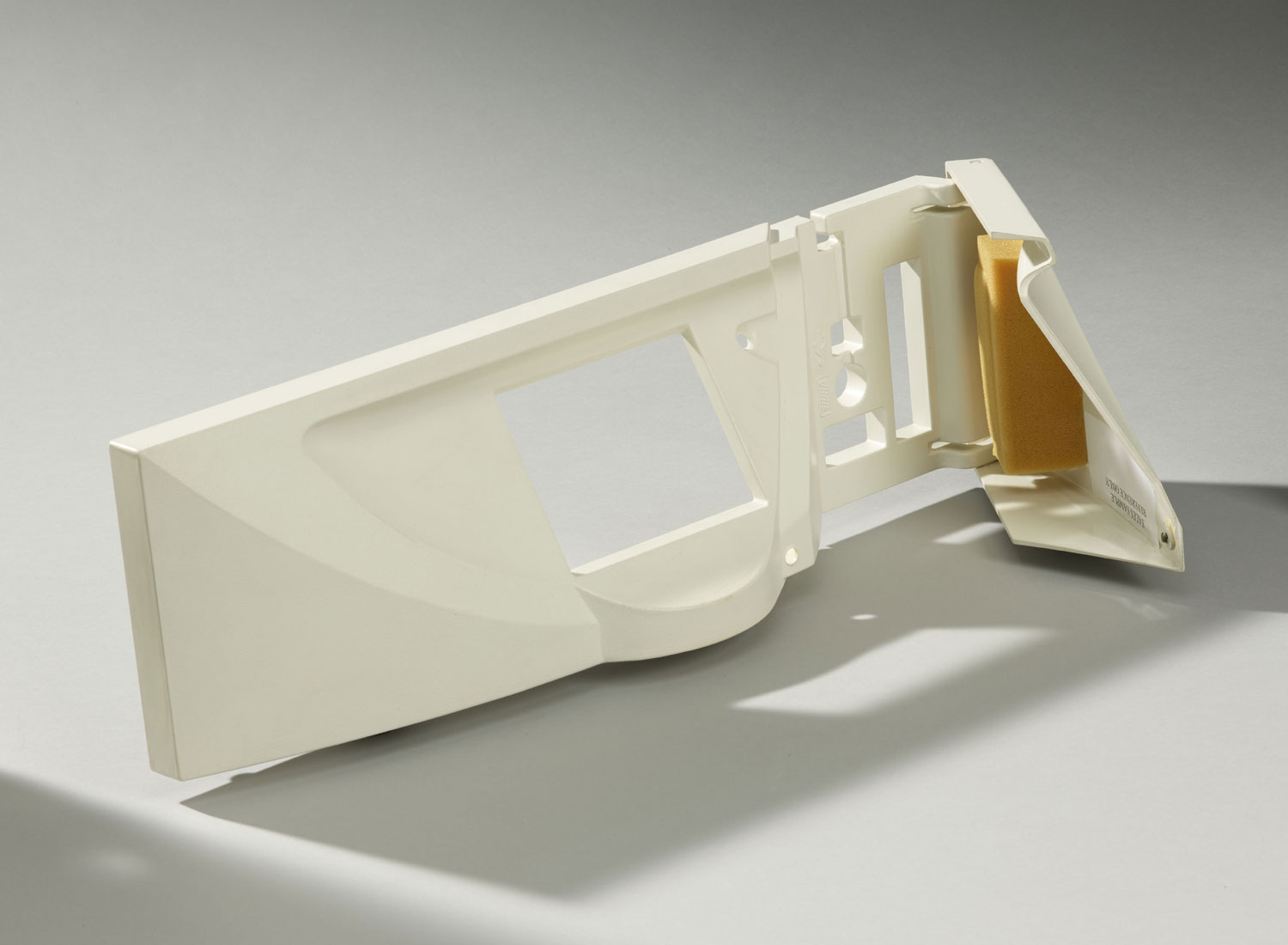

- Aircraft Seating Components:

- Seat-backs, video bezels, and snack trays.

- Impact-resistant plastic parts.

- Comfort-enhancing designs for first-class and business-class seating.

- Weight Savings:

- Pressure-formed materials are lighter, saving energy for the aerospace industry.

Customer Focus and Expertise:

With our extensive experience in working with airline-industry seating integrators, we understand the unique requirements of the aerospace industry. We offer the following customer-focused benefits:

- Value Engineering: We review your design and provide advice to enhance manufacturability and speed up part production.

- Industry Partnerships: Our seating components are trusted by leading airlines, including Air China, Air France, British Airways, Lufthansa, and Qatar.

- Global Reach: Our products travel worldwide, ensuring reliability and performance across different airlines.

Choose CW Thomas for Thermoforming Excellence

When it comes to thermoforming solutions for the aerospace industry, CW Thomas stands out as a trusted partner. With our pressure forming expertise, commitment to quality and safety, and dedication to meeting customer needs, we deliver comfort, safety, and refined aesthetics to the world of aircraft seating. Contact us today to discuss your project and experience the benefits of pressure forming.