Thermoformed Heavy-Gauge Plastic Parts for OEMs and Industrial Applications

TRUSTED BY LARGE AND SMALL ORGANIZATIONS WORLDWIDE

Unlock the Potential of OEM and Industrial Applications:

Experience the versatility of our thermoforming capabilities across a wide range of applications, including:

- Aircraft Seating Components: Enhance the functionality and aesthetics of seating in various aircraft classes.

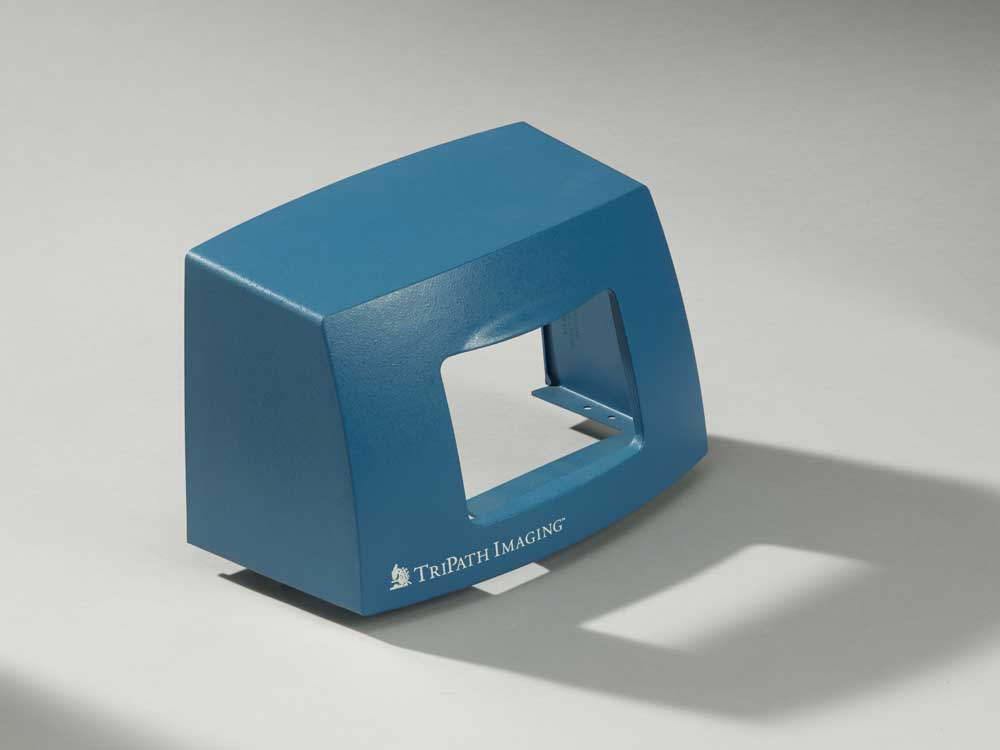

- Medical Device Enclosures: Ensure reliable protection for medical devices, dispensers, taillights, and electrical boxes.

- Custom Inserts: Optimize the performance of refrigerators, laboratory shakers, and in vitro diagnostic equipment.

- Protective Covers: Safeguard dispensers, exhaust systems, and cab fronts with durable plastic covers.

- Industrial Guards: Protect motors, gears, and fan belts with precision-fit guards.

- Dashboards for Equipment: Achieve superior control and durability in construction equipment and forklifts.

- ATM Machine Covers: Safeguard sensitive equipment with custom-made covers.

- Specialized Trays: Optimize bread-proofing processes with tailor-made trays.

- Rail Transit Components: Contribute to a reliable and aesthetically pleasing rail transit experience with window masks, ceiling and side panels, and other interior parts.

From Concept to Reality:

Transform your initial design, whether it’s a simple sketch or detailed CAD drawings, into a fully realized product with our streamlined process:

Collaborative Design Review: We partner with you to explore design enhancements, improve manufacturability, and accelerate time to market.

In-House Tooling Expertise: Our skilled team designs and builds precise tooling, ensuring accurate and efficient production.

Rapid Prototyping: Swiftly validate your design through rapid prototyping, allowing for efficient iterations and adjustments.

Seamless Manufacturing and Assembly: Once your final design is approved, we seamlessly move into production and assembly, providing a turnkey solution tailored to your needs.

Have a technical Question? Ask Us

Uncompromising Quality for Peace of Mind:

Rest assured that your project is in capable hands, backed by our commitment to delivering impeccable quality:

- Certified Quality Management: Our ISO 9001:2015 and AS:9100 certifications validate our dedication to upholding stringent standards throughout the manufacturing process.

- Robust Quality Control: From design to final packaging, our comprehensive quality control procedures ensure your product meets or exceeds engineering and technical specifications.

Choose CW Thomas for Thermoforming Excellence

Partner with CW Thomas, where your success is our priority. Unlock the potential of thermoformed heavy-gauge plastic parts for OEMs and industrial applications, benefit from our collaborative approach, and rely on our unwavering commitment to delivering superior quality. Contact us today to discuss your project and experience the customer-focused excellence of CW Thomas.