Heavy Gauge Thermoforming

Your Partner in Innovation: High-Quality, Cost-Effective Thermoforming for Complex Projects

Precision and Durability for Your Largest Projects

At C.W. Thomas, we specialize in heavy gauge thermoforming, providing robust and cost-effective solutions for your most demanding applications. Our expertise and advanced technology ensure that each part we produce meets the highest standards of precision and durability, making us a trusted partner in the manufacturing industry.

What is Heavy Gauge Thermoforming?

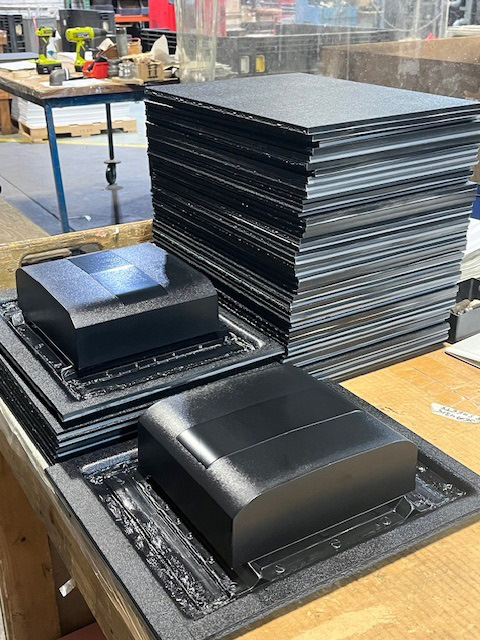

Heavy gauge thermoforming involves forming plastic sheets with a thickness of 0.060 inches up to 0.500 inches. This process is ideal for creating durable parts that are used in a wide range of industries, offering excellent material properties and design flexibility.

CW Thomas produces part sizes measuring inches to multiple feet. Our largest Rotary Machine can vacuum and/or pressure form a sheet measuring 60 inches x 108 inches and produce a part with a height of 25 inches.

Heavy Gauge Thermoforming for Today’s Industry Leaders

Benefits of Heavy Gauge Thermoforming

Superior Durability

- High-Strength Materials: We utilize high-quality polymers, including high-temperature materials, ensuring that your parts are exceptionally durable and can withstand harsh conditions.

- Long-Lasting Performance: Our thermoforming process produces parts that offer long-lasting performance, reducing the need for frequent replacements and maintenance.

Cost-Effective Solutions

- Lower Tooling Costs: Compared to injection molding, heavy gauge thermoforming requires significantly lower tooling costs, making it a more economical option for large parts.

- Efficient Production: Thermoforming allows for efficient production processes, reducing material waste and overall manufacturing costs.

Design Flexibility

- Complex Shapes: Our advanced thermoforming techniques allow for the creation of complex and detailed shapes, providing greater design flexibility for your projects.

- Customization Options: We offer a wide range of customization options, including various textures, finishes, and colors, to meet your specific needs and preferences.

Our Capabilities

Advanced Technology and Expertise

- State-of-the-Art Equipment: Our facility is equipped with the latest thermoforming machinery, ensuring precision and consistency in every part we produce.

- Experienced Team: Our team of engineers and technicians bring extensive experience and expertise to every project, delivering exceptional results tailored to your requirements.

Wide Range of Materials

- Versatile Polymers: We work with a variety of polymers, including those with high-temperature resistance, to provide the best solutions for your specific applications.

- Material Selection Assistance: Our experts assist in selecting the right material for your project, ensuring optimal performance and durability.

Have a technical Question? Ask Us

Applications of Heavy Gauge Thermoforming

Serving Diverse Industries

Our heavy gauge thermoforming solutions are ideal for producing large, durable parts used across various industries, including:

- Automotive: Durable dashboards, door panels, and other large automotive components.

- Aerospace: Lightweight, high-strength parts for aircraft interiors.

- Medical: Sterile enclosures and equipment housings for medical applications.

- Industrial: Heavy-duty parts for machinery and equipment.

- Recreational Vehicles (RVs): Robust panels, enclosures, and other large components.

Why Choose C.W. Thomas?

Customer-Focused Approach

- Collaborative Partnership: We work closely with our customers from the initial concept to the final product, ensuring that all requirements are met with precision and excellence.

- Exceptional Support: Our dedicated team is committed to providing outstanding customer service and support throughout the entire process.

Proven Expertise

- Decades of Experience: With over four decades of experience in thermoforming, we have a proven track record of delivering high-quality, durable parts for various applications.

- Satisfied Clients: Our commitment to quality and customer satisfaction has earned us a reputation as a reliable and trusted partner in the industry.

Contact Us

Ready to explore the benefits of heavy gauge thermoforming for your next project? Contact C.W. Thomas today to discuss your needs and discover how our innovative solutions can enhance your business. Our team of experts is here to provide the support and expertise you need to achieve outstanding results.