Thermoforming Solutions for the Mass Transit Industry

As a leader in thermoforming, CW Thomas has been at the forefront of providing custom plastic components for the mass transit industry. From buses and trains to light rail systems, we specialize in creating durable, lightweight, and cost-effective thermoformed solutions that meet the rigorous safety, performance, and aesthetic requirements of modern transit systems.

TRUSTED BY LARGE AND SMALL ORGANIZATIONS WORLDWIDE

Key Applications for the Mass Transit Industry

CW Thomas offers a range of thermoformed solutions specifically designed to meet the unique challenges of the mass transit industry, ensuring safety, durability, and enhanced passenger experience:

- Ceiling and Wall Panels:

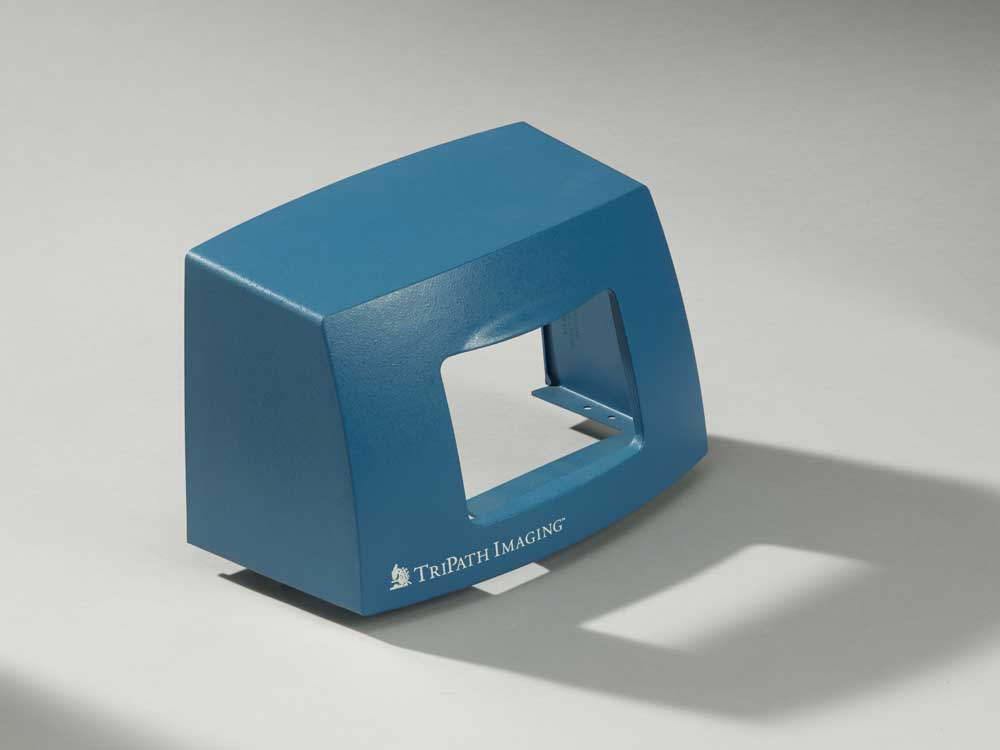

CW Thomas produces high-quality thermoformed ceiling and wall panels designed to meet the stringent demands of mass transit vehicles. Our panels are engineered for durability, impact resistance, and ease of installation, ensuring they withstand the rigors of daily use while maintaining an appealing aesthetic. Available in a variety of textures and finishes, our panels can be customized to match specific interior designs, improving the passenger experience and the overall look of the transit system. - Window Masks, Baggage Racks, and Seating Components:

The mass transit environment demands solutions that combine functionality with a sleek design. CW Thomas manufactures window masks, baggage racks, and seating components that are lightweight yet strong enough to endure constant use. Our thermoformed parts are tailored to meet each client’s unique needs, offering easy-to-clean surfaces and a high level of customization to ensure comfort and safety for passengers while optimizing space and design. - Ventilation Components:

Effective ventilation is critical in public transportation. CW Thomas provides thermoformed ventilation components that offer high performance and reliability. Our solutions are designed to fit seamlessly into mass transit vehicles, enhancing air circulation and passenger comfort while maintaining the vehicle’s interior design standards. These components are built to ensure long-lasting durability in high-traffic environments.

Material Advantages: Low Toxicity & High Durability:

At CW Thomas, we understand the importance of safety and durability in the mass transit industry. That’s why we use low-toxic, fire-retardant materials to ensure that all our components meet or exceed safety regulations. Our materials are not only designed for passenger safety but are also chosen for their durability, able to withstand the wear and tear of heavy daily use. This combination of safety and durability ensures that our thermoformed components provide long-term value for transit operators.

Commitment to Quality

When it comes to mass transit, quality is paramount. CW Thomas upholds the highest standards in the manufacturing process, with rigorous quality checks at every stage of production. From the initial design phase to the final product, we implement a thorough inspection process to ensure that every part we manufacture meets the specific requirements and safety standards of the mass transit industry. Our commitment to quality ensures that our clients receive products that perform reliably over the long term, reducing maintenance costs and ensuring passenger safety.

Certified Quality Management: Our ISO 9001:2015 and AS:9100 certifications validate our dedication to upholding stringent standards throughout the manufacturing process.

Robust Quality Control: From design to final packaging, our comprehensive quality control procedures ensure your product meets or exceeds engineering and technical specifications.

Why Choose CW Thomas for Your Mass Transit Projects?

- Customizable Solutions:

We understand that every mass transit project is unique. Our team works closely with clients to create customized thermoformed components that meet specific design, material, and performance requirements. - Durability and Safety:

Our components are built to last, using materials that are both durable and safe for passengers, ensuring they stand up to the toughest conditions. - Aesthetics and Functionality:

We combine cutting-edge technology with design expertise to deliver components that enhance both the functionality and appearance of mass transit vehicles. - Quality Assurance:

CW Thomas employs strict quality control processes to guarantee that every component we manufacture is of the highest quality, ensuring reliable performance and safety.

Partner with CW Thomas for Your Mass Transit Needs

With decades of experience and a commitment to excellence, CW Thomas is the trusted partner for thermoforming solutions in the mass transit industry. Our innovative, high-quality components help improve the safety, functionality, and aesthetics of transit vehicles around the world.

Let CW Thomas help you bring your next mass transit project to life. Contact us today to learn more about how our thermoformed solutions can meet the unique demands of the transit industry.

.