Thermoforming Materials: A Comprehensive Guide

What are thermoforming materials?

Thermoforming, a widely used process for molding plastics, offers the flexibility to utilize various materials tailored to the specific needs of each project. This guide delves into six key materials used in thermoforming: Polycarbonate, Kydex, High-Density Polyethylene (HDPE), Acrylonitrile Butadiene Styrene (ABS), Acrylic, and Polyvinyl Chloride (PVC). For each, we will explore an overview of the material, pros, cons, applications, and technical details.

Vacuum Forming for Today’s Industry Leaders

Polycarbonate Thermoforming

The Lowest-Cost Tooling

Polycarbonate is a clear, strong and tough material known for its superior strength and high-temperature resistance. It’s a versatile plastic used in a broad range of applications for its exceptional clarity and aesthetic appeal.

Pros: Superior strength, high toughness, excellent temperature resistance, clear aesthetics.

Cons: Prone to scratches, lower chemical resistance.

Applications: Bullet-resistant windows, safety guards, eyewear, electronics.

Polycarbonate Technical Details:

- Heat Deflection Temp at 264 psi: 270°F (132°C)

- Rockwell Hardness: R118

- Tensile Strength: 8,000-9,500 psi

- Specific Gravity: Varies based on the specific type, generally between 1.2 and 1.22

Kydex Thermoforming

Kydex is a line of thermoplastic acrylic-polyvinyl chloride materials known for their durability and customization possibilities. This material is highly resistant to impact and abrasion, ensuring long-term performance.

Pros: High resistance against impact and abrasion, durability, customization.

Cons: Less rigidity compared to other materials.

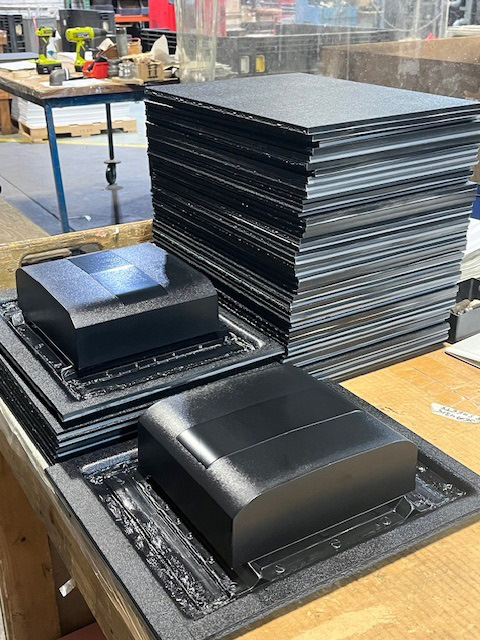

Applications: Firearm holsters, electronic equipment housings, aircraft interiors.

Kydex Technical Details:

- Heat Deflection Temp at 264 psi: 173°F (78°C)

- Rockwell Hardness: R105

- Tensile Strength: 6,100 psi

- Specific Gravity: 1.34

What do you need thermoformed?

High-Density Polyethylene (HDPE Thermoforming)

HDPE, or High-Density Polyethylene, is a versatile and eco-friendly plastic that offers an impressive strength-to-density ratio. It’s used in everything from milk jugs to fuel tanks due to its exceptional durability and chemical resistance.

Pros: High strength-to-density ratio, impact and chemical resistance, environmentally friendly.

Cons: Can warp under high heat.

Applications: Outdoor equipment, cutting boards, storage containers.

Technical Details:

- Heat Deflection Temp at 66 psi: 125°F (51°C)

- Rockwell Hardness: R62

- Tensile Strength: 4,600 psi

- Specific Gravity: 0.95

Acrylonitrile Butadiene Styrene (ABS Thermoforming)

Acrylic, also known as plexiglass, is a transparent plastic characterized by its optical clarity and light transmission. It is an excellent choice for applications where aesthetics matter.

Pros: Excellent optical clarity and light transmission, resistance to weathering and UV light.

Cons: Prone to scratching, less impact resistant.

Applications: Signage, aquariums, display cases.

Acrylic Technical Details:

- Heat Deflection Temp at 264 psi: 195°F (90.5°C)

- Rockwell Hardness: M95

- Tensile Strength: 10,500 psi

- Specific Gravity: 1.18

Polyethylene Terephthalate Glycol (PETG)

PETG is a durable and clear plastic widely used in various industries, offering excellent chemical resistance and clarity. It is often chosen for its ease of thermoforming and its ability to be sterilized, making it suitable for medical and food-related applications.

Pros: Excellent clarity and transparency, Strong chemical resistance, Easily thermoformed, Impact-resistant, Can be sterilized, making it suitable for medical applications

Cons: Lower heat resistance compared to some other plastics, Susceptible to scratching without proper coating, Can be more expensive than alternatives like PVC

Applications: Medical devices and trays, Food packaging, Point-of-purchase displays, Machine guards, Prosthetic components

Technical Details:

- Heat Deflection Temp at 264 psi: 155°F (68°C)

- Rockwell Hardness: R107

- Tensile Strength: 7,700 psi

- Specific Gravity: 1.27

Thermoforming Material Comparison Table

| Material | Heat Deflection Temp at 264 psi (°F/°C) | Rockwell Hardness | Tensile Strength (psi) | Specific Gravity |

|---|---|---|---|---|

| Polycarbonate | 270/132 | R118 | 8,000-9,500 | N/A |

| Kydex | 173/78 | R105 | 6,100 | 1.34 |

| HDPE | 125/51 | R62 | 4,600 | 0.95 |

| ABS | 190/88 | R105 | 7,600 | 1.05 |

| Acrylic | 195/90.5 | M95 | 10,500 | 1.18 |

We hope this guide helps you understand the vast range of materials available for thermoforming and their unique characteristics. At CWThomas, we’re committed to providing the best material for your specific application.