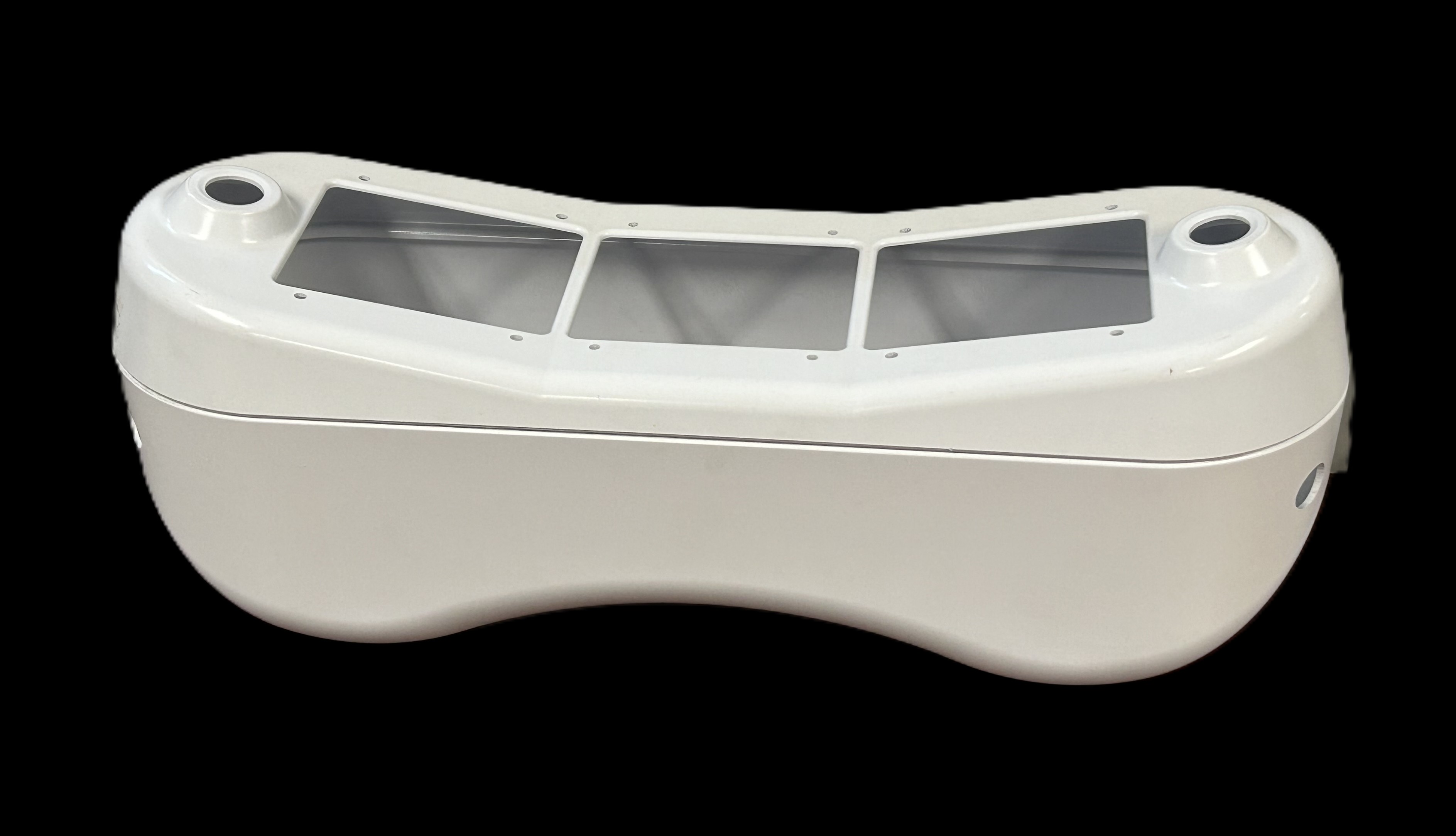

At CW Thomas, we specialize in converting traditional metal components into high-performance thermoformed plastic parts. This transition offers significant benefits, including reduced weight, cost savings, and greater design versatility.

Our Metal-to-Plastic Conversion Process

- Evaluation & Feasibility

Our team assesses your existing metal components design to identify opportunities for conversion and improvement. - Material Selection

Selecting the correct material is an integral part of the process. We will identify viable options based on your needs, whether its temperature resistance, UV rated, strength or other critical characteristics for your project. - Design Optimization

The part is re-engineered for thermoforming, incorporating enhancements that improve strength, function, and manufacturability. - Prototyping & Testing

Prototype parts are created and tested to ensure quality, precision, and compliance with industry standards. - Full-Scale Production

Once the design is validated, we move to production, delivering high-quality plastic components with consistent performance to maximize results.

Why Convert Metal Parts to Plastic?

- Lighter Weight – Reduces handling challenges and transportation costs.

- Lower Costs – Lower tooling costs, more efficient manufacturing and material usage help cut expenses.

- Greater Design Freedom – Enables complex shapes and integrated features that are difficult to achieve with metal.

- Corrosion & Chemical Resistance – Plastics resist environmental wear, improving longevity.

Why Choose CW Thomas?

With over 75 years of experience, CW Thomas is a leader in custom thermoforming solutions. Our state-of-the-art facility in Pennsylvania is equipped with cutting-edge technology that allows us to deliver precision-engineered plastic components for industries such as medical, aerospace, transportation, and industrial equipment.

- In-House Engineering & Design Support – We collaborate with clients to optimize designs for performance and manufacturability.

- Comprehensive Quality Control – Our ISO-certified processes ensure reliable and consistent results.

- Custom Solutions for Every Industry – We tailor our thermoforming solutions to meet the unique needs of each application.

- End-to-End Manufacturing – From concept to production, we handle every step of the process under one roof.

CW Thomas is your trusted partner in metal-to-plastic conversion. Contact us today to discover how we can help improve your products with innovative thermoforming solutions.